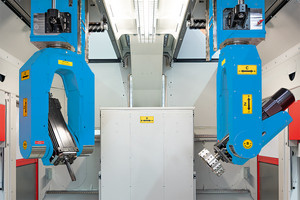

Main units

5-axis unit

The air-cooled PBA main unit with spindle drive is rated at 63 kW, with a stepless speed range of 0 to 12,000 rpm. Up to a speed of 3,000 rpm, the spindle motor can provide a maximum torque of approx. 150 Nm; or approx. 50 Nm at 12,000 rpm. A wide range of tools such as saw blades, cylindrical mills, drills, end mills, disc cutters, dovetail cutters as well as chainsaws etc. can be exchanged by means of an HSK-80-E tool holder. Tool management and selection occurs in Hundegger's CAMBIUM production software. Depending upon the requirements of the part to be processed, the suitable tool from the tool-change magazine is automatically switched. Besides type, diameter, length and magazine slot, characteristic data of the milling or drilling tools includes the optimal speed, which is called up automatically when the respective tool is used. This flexibility ideally suits the PBA 5-axis unit to the widest range of applications and processing purposes. Operations are executed on 6 part sides in a single clamping.

Automatic tool changer with magazine for up to 35 tools

The tool is taken from the magazine based on the program. The tool magazine also moves on the gantry. This minimizes the time required for tool changes. Drills, end mills, side milling cutters, dovetail cutters etc. can be used here with HSK-63 E or HSK-80 E tool holders. A total of 30 positions distributed over 2 disc magazines are available for standard tools. Below the 2 disc magazines, the changer can also be automatically loaded with 4 large tools. On the outside of the changer there is space for an exchangeable deep drill unit (NL 1,250 mm).

Possible allocation:

- 2 circular saw blades, max. diameter 1,100 mm

- 1 angle milling head 90°

- 1 chain blade with effective length 500 mm

The tool magazine is equipped with a separate X-axis driven by a servo motor. This enables all tools to be provided for an additional 5-axis main unit (optional).