Main units

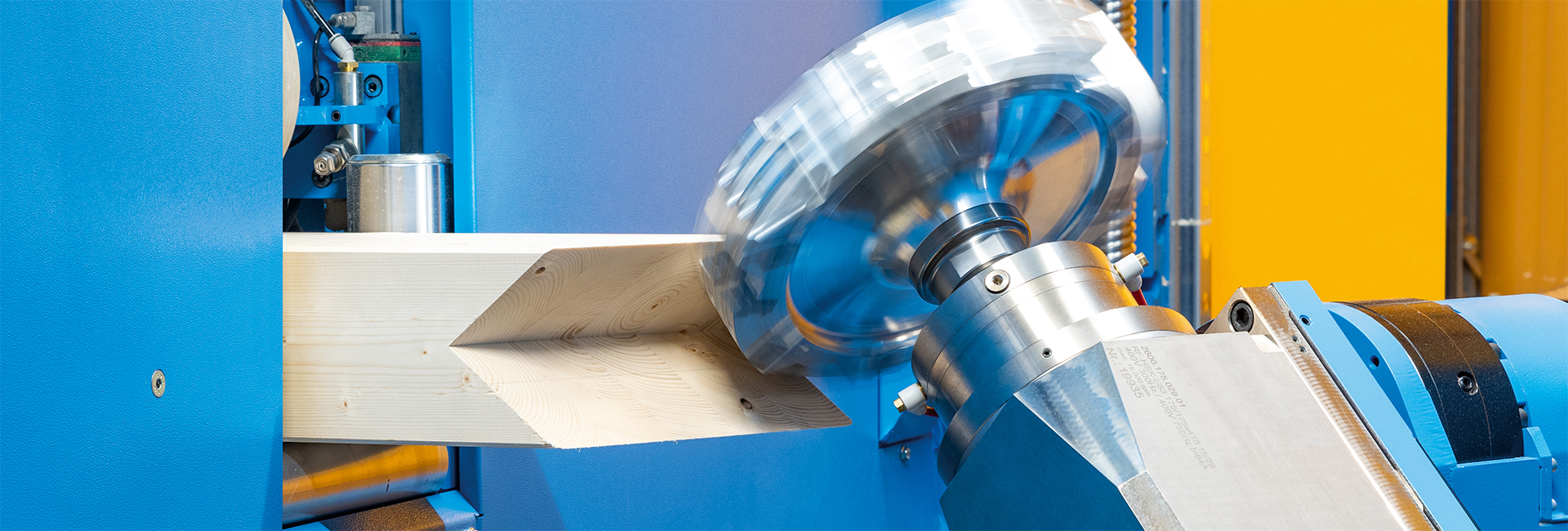

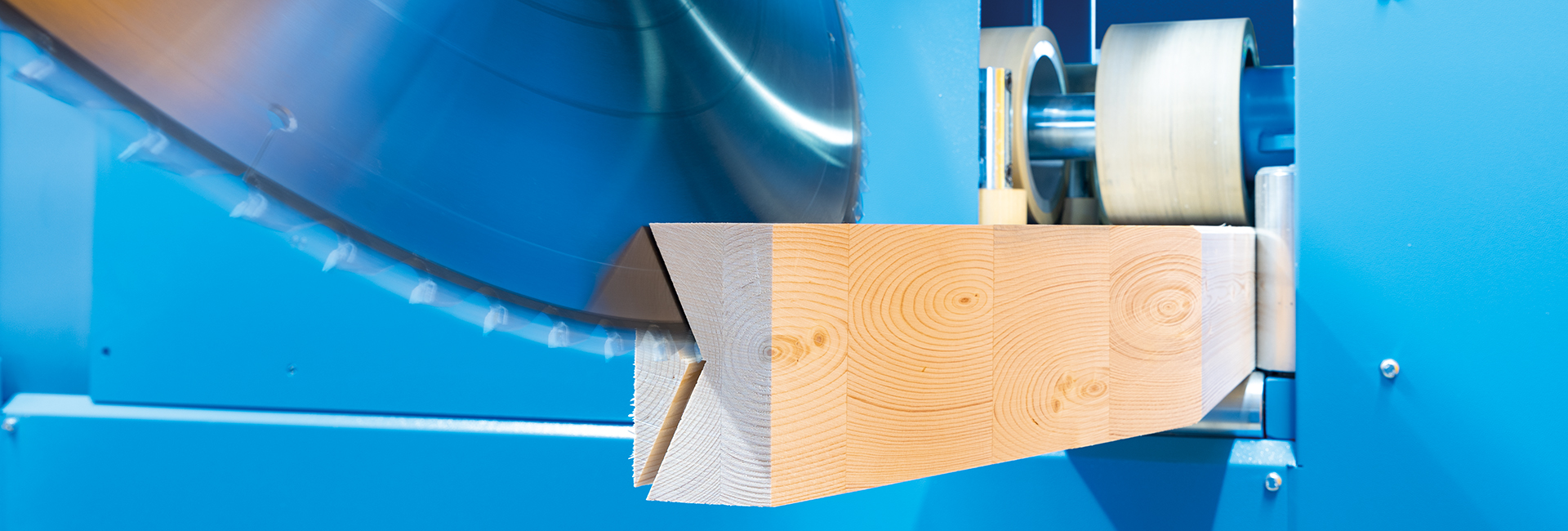

5-axis saw/slot/marking device

The overhead 5-axis saw/slot/marking unit with a drive rating of 13 kW further increases the throughput of the ROBOT-Drive.

The flangeless saw blade with a diameter of 800 mm is excellently suited to slot cutting and segmenting as well as cutting to length.

The 5-axis unit can be rotated through 360° and at the same time tilted by 180°. In addition to all conceivable chop, mitre and compound cuts, this also enables birdsmouths, roof ridge joints, eaves formwork notches, scarf joints and so on to be made – quickly, precisely and in high quality.

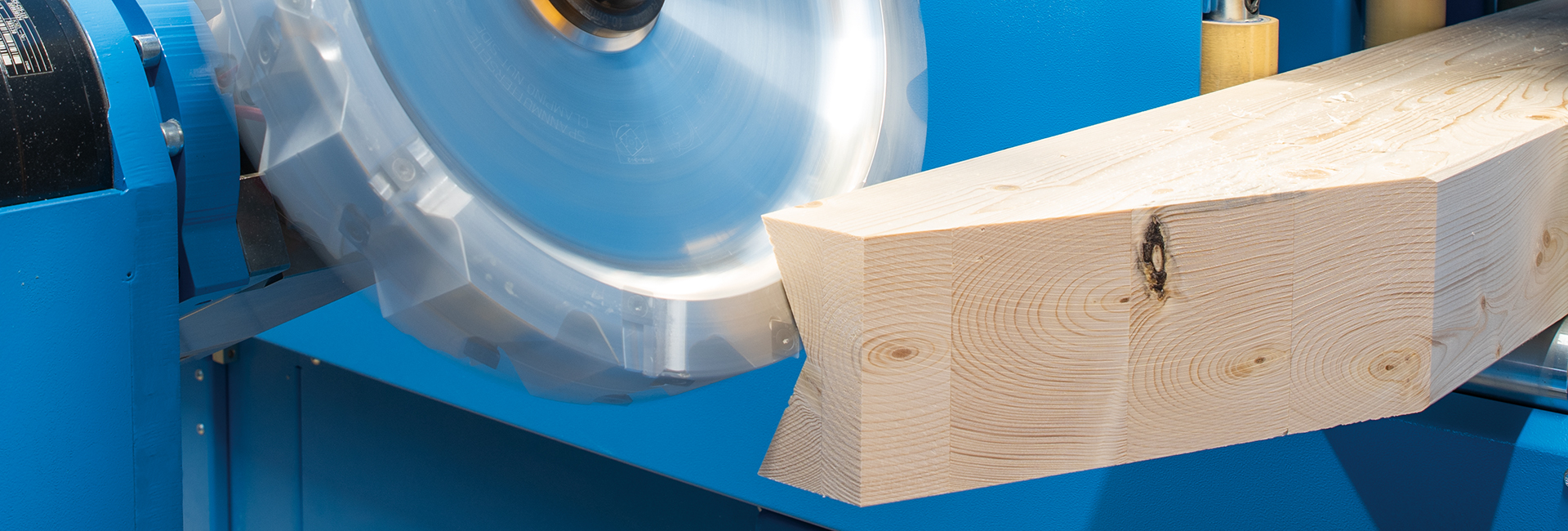

The patented 6-axis ROBOT unit

The ROBOT unit with a standard power rating of 12 kW (option of 29 kW) and infinitely variable speed from 0 to 12,000 rpm (15,000 rpm) caters for every need.

The magazine of the tool changer can hold 16 different tools with a length of up to 420 mm. In combination with HSK-63-E tool holders, the tool changer can change over saw blades, drill bits, end mills, side milling cutters, dovetail mills, cylindrical mills and markers for labelling parts in seconds.

The tools are selected and managed in the Hundegger production program CAMBIUM®.

Depending on the type of processing to be performed, the machine automatically selects the appropriate tool from the magazine. Apart from the type, diameter, length and tool position in the magazine, the characteristic data of the milling and drilling tools also includes the optimal speed. The speed is called up automatically when the respective tool is used.