COMBI-SUPPORT FOR HORIZONTALLY WORKING TOOLS

Three units plus stylus and inkjet can be mounted. Each unit can be equipped with drilling, slotting or milling tools at will. The computer controlled power stroke makes even all kinds of blind holes, countersinks or ring dowel milling possible.

Drilling units

The support can be equipped with two different drill units. Here the drills are always guided in a turret drill bush directly on the part.

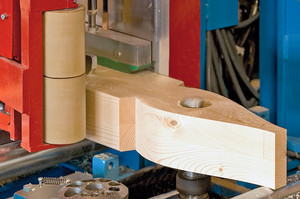

Swivelling drilling unit

The swivelling drilling unit enables precise side drilling up to an angle of 45°.

- max. angle 45°

- max. drill length 650 mm for 650 mm version

- max. drill length 830 mm for 830 mm version

Deep hole drilling device

For through holes for up to 1,300 mm part width.

Standard slot cutter

Slot chains in various sizes can be mounted on this unit. Machining can take place on 4 sides of the part. Likewise, hidden slots are possible.

Guided slot cutter

During through slotting, the bar is fully automatic fixed on the operator side and the wood is accordingly moved continuously in longitudinal direction, which minimizes the operating time. Even hidden slots as well as the piercing operation are possible as before.

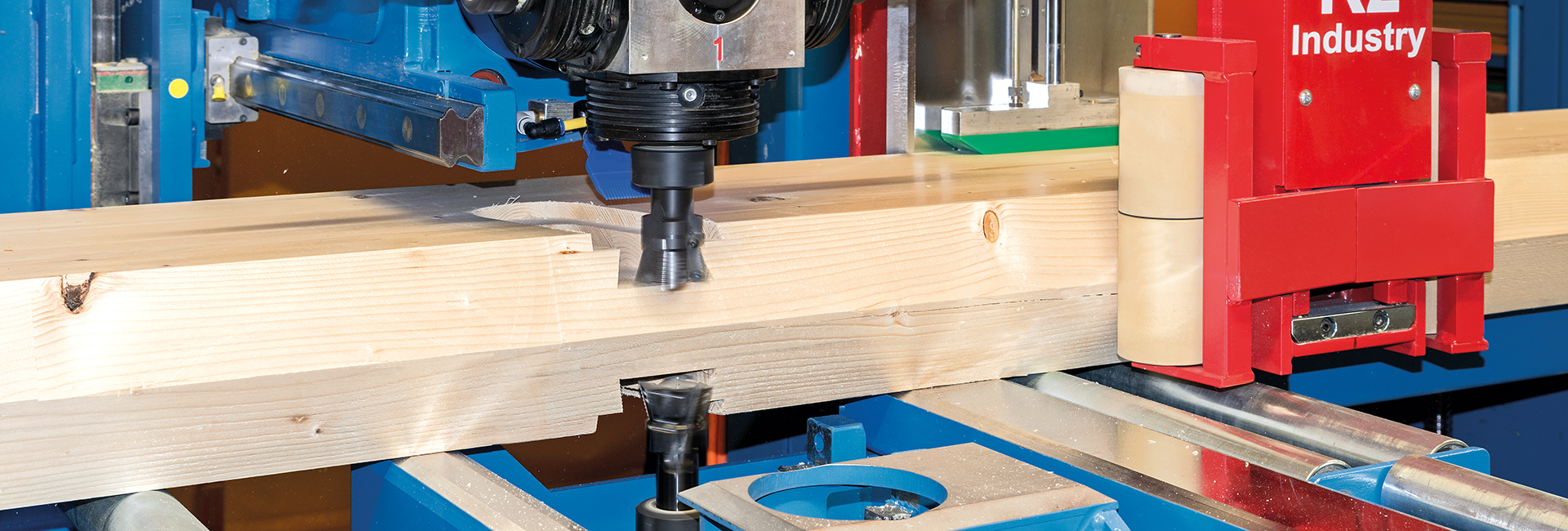

COMBI-SUPPORT FOR VERTICALLY WORKING TOOLS

Up to five units can be mounted on the vertical combi-support. Each unit can be equipped with drilling, slotting or milling tools at will. The computer controlled power stroke makes even all kinds of blind holes, countersinks or ring dowel milling possible. All kinds of profiles including the freely defined ones can be machined with the end mill (free end mills).

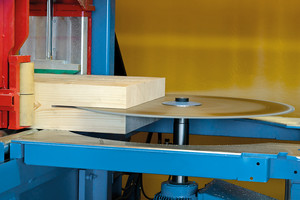

Horizontal saw

With the horizontal saw, it is possible to work on 4 sides of the part, on sides 2 and 4 as well as the two end faces. Clean slots up to 300 mm deep can be machined quickly with the large horizontal saw. If slots up to 145 mm deep are sufficient, even the combi-support can be equipped with a corresponding unit with saw blade.

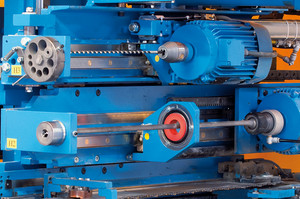

Double support

For corresponding operations, the double support offers a substantial time saving, since it is possible to machine on two different sides of the part at the same time (synchronously). For synchronous motion, the tools on opposite sides must be identical. The double support can be equipped with a maximum of three drilling and/or milling units.

Log home unit

Consisting of 2 vertical and 2 horizontal mills for 4-axis rabbeting of log house planks. Two milling operations can be carried out simultaneously from opposite directions. Horizontal as well as vertical. The 4 mills can, however, function separately independently of each other and can be be set to the desired milling depth thus it is also possible to rabbet on one, two or three sides. The mills can be customized. The stroke is effected hydraulically.

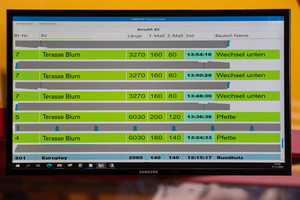

Dimensional measurement

With this unit, the dimension (width and height) is checked automatically for the timber cross-section. If deviations outside the selected tolerance (can be set in machine data) are determined, the machine stops and the cross-section deviation is displayed. In the case of cross-section deviations within the specified tolerance, the part is processed with the determined tolerance. Thus accurate machining is achieved without manual cross-section correction.

Because a reference side (joinery side) can be assigned, the part is automatically turned if it is wrongly positioned (upright or lying). The advantage is that

e.g. tenons are always exactly centred on the part.