OPTIONS

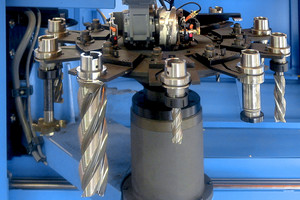

Automatic tool changer for 5-axis unit

The tool needed for processing is selected from the magazine, under control of the software program. The tool magazine moves along with the gantry, minimising the tool-change time. Up to 16 tools can be installed, including drill bits, end mills, side milling cutters, dovetail mills etc. via HSK-80 tool adapter.

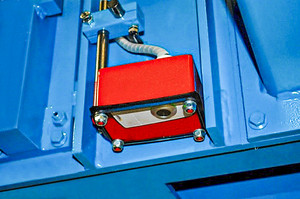

Vertical drilling unit

With a 3 kW drill motor. The unit is equipped with a quick-change drill chuck and a hardened turret drill guide. The working stroke is pneumatic and computer-controlled. The machining depth is recorded encoder measuring absolute values, so that blind holes can also be drilled. The speed of the frequency-controlled motor can be optimally and steplessly adjusted in the range of 750-3000 rpm to the respective drill.

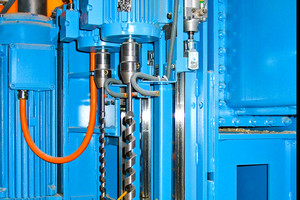

Deep hole drilling device

The deep hole drilling unit is designed for drilling depths of up to 1000 mm and for drills from Ø12 mm to Ø40 mm. It is fitted with a 3 kW drill motor. Due to the swivel range of 360°, horizontal holes can be drilled on all sides of the part. The chips are removed by compressed air, which is supplied through the interior of the drill.

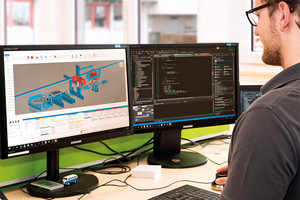

Remote maintenance

The remote maintenance enables a remote display of the screen contents of the control panel computer. This makes it possible, for example, for Hundegger to see the current job or individual part, or for the Hundegger service department to check the machine data or to change the system settings. It is also possible for the customer to see the service employee’s screen. In this way, settings or changes to the part input carried out by Hundegger can be followed by the machine operator. The scope of delivery also includes a portable device with camera function, which enables videos of machine processes to be recorded.